Five Things You Never Knew About Your Local Quarry

January 22, 2018

That’s Made of WHAT?? Things You Never Knew We Made From Limestone

February 8, 2018Limestone

Limestone is a sedimentary rock mainly made out of calcium carbonate and occasionally magnesium. The majority of limestone derives its origin from a biochemical nature, meaning the calcium carbonate within the stone originated from ancient shelled oceanic creatures.

Due to the high calcium content in limestone, it normally appears light in color, although numerous aesthetic variations exist.

As a leading stone produced in the United States, limestone accounts for 42% of all domestic aggregate production. Aggregates are made from high-quality, natural limestone deposits, similar to those found in the Lake Belt region of western Miami-Dade County.

Limestone is most commonly utilized as a rough block for building and construction. This includes amenities we all use every day: road materials (for interstates), housing, buildings, schools, hospitals, airports, shopping malls, etc.

The limestone production process can fundamentally be broken down into two generalized phases: quarrying, and processing.

Limestone Quarrying

The quarrying process is also known as “extraction.” This procedure consists of removing blocks or large pieces of stone from a previously identified geological deposit. The different methods used to quarry or extract the limestone depends on the specific properties of the limestone deposit itself, including density, bedding planes, and depth. Additional considerations include financial and environmental conditions.

In general, the limestone quarrying process is quite simple: locate or create minimal breaks in the stone, then remove and secure the stone for transport.

Access to the limestone deposits is gained by removing a layer of earth, vegetation, and rock that is unsuitable for product production. This material is stored onsite to use later during reclamation of the quarrying site.

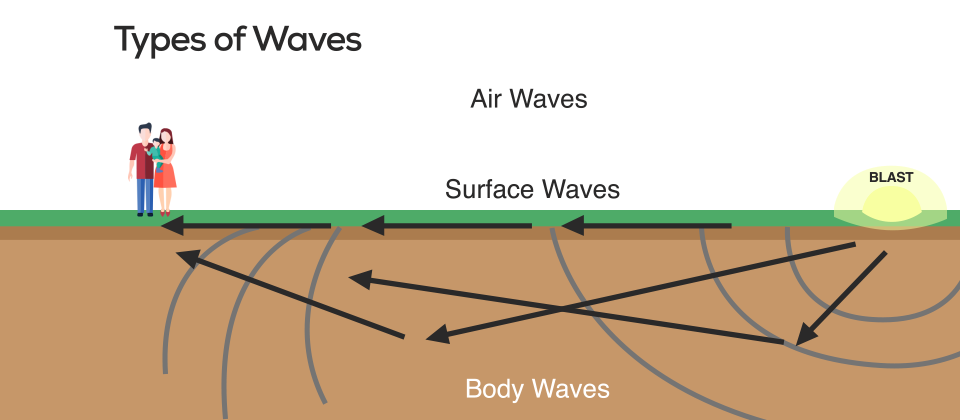

This top layer is removed using heavy machinery coupled with small, highly-controlled explosive charges. Once the limestone is exposed, the limestone can be removed from the quarry and made into aggregates.

Limestone is generally either pulled or cut from these locations using saws, hydraulic splitters, as well as forklifts and other heavy machinery to pry up the blocks from the earth. Then the limestone is transferred to an inspection area for grading and shipment from the site.

Limestone that is considered insufficient in quality or size is stored for future use, or crushed and made into aggregates like concrete, paving materials, and other construction applications.

Limestone Processing

Limestone processing begins with cutting the material.

Some limestone blocks are cut into slabs before reaching the fabrication stage. Other limestone deposits are crushed and sent to be made into concrete, other materials for use in construction applications, crude oil, etc.

Building and Construction

High-quality limestone deposits are quarried to service the need for the building and construction industries. Certain types of limestone, like the deposits found in The Lake Belt, can be cut into blocks. Additionally, the remaining limestone aggregate is an essential ingredient in the base material for building and construction purposes.

Lower-grade limestone may contain clay. This is used in the production of cement, an essential ingredient for concrete. Concrete is poured to serve as roadways, sidewalks building foundations, structural beams, and columns for facilities all of us use every day.

Agricultural

Limestone deposits can additionally be used for agricultural use by the farming sector. By crushing limestone, various grades based on the particle size are produced. These products are known as agricultural lime.

Soil acidity influences plant and crop growth, potentially limiting production. Farmers spread agricultural lime onto the soil, using the calcium carbonate content in the limestone to neutralize the soil acidity.

Spreading limestone additionally frees up soil minerals like phosphates, and enabled their absorption into plants and crops and helping them grow.

Manufactured Goods

Very high-grade limestone is produced from western Miami-Dade County. Some of this limestone is quarried and ground into a fine powder, which is then used for a multitude of uses in manufactured goods such as paints, plastics, household cleaners, as well as the carpets in our vehicles and homes.

A Day in the Life

No naturally formed rock provides as many uses or the versatility of limestone. Limestone aggregate represents an integral part of our daily lives.

Limestone is an essential ingredient to the foundations of our homes, hospitals, schools, post offices, and any other human-made structure you could think of.

In the United States, Florida is the 2nd leading producer of limestone aggregate and the 4th leading consumer.

Population expansion means more individuals and families are moving into our area. It means more people are buying homes, driving on our roads, enrolling their children in our schools.

With so many uses for limestone, and its status as a vitally important ingredient in so many of the things we use, limestone products and aggregate materials are virtually irreplaceable in our lives today.